Heat Exchangers – General Information

Heat Exchangers are devices that we use το attain heat transfer between a solid object and a fluid, or between two or more fluids. According to the 2nd Thermodynamic Principle, for this transfer to occur, there must be a temperature differential between the exchanged fluids.

The most common example of a Heat Exchanger can be found in a 4 – stroke car engine that is water-cooled. The circulating fluid here is the typical engine – coolant that flows through the radiator of the car’s engine. As a result, incoming air cools the radiator coils where the engine coolant circulates, effectively transferring heat from the coolant into the air medium.

A Marine Heat Exchanger is not very different from a standard non-marine one except that it is found aboard ships and vessels. Heat Exchangers aboard ships can be used for heating as well as cooling water and oil. Common applications for marine heat exchangers are oil coolers, water coolers, air coolers, vapor heaters, and others. The two most common types used in the marine industry are Plate and Shell & Tube, exchangers.

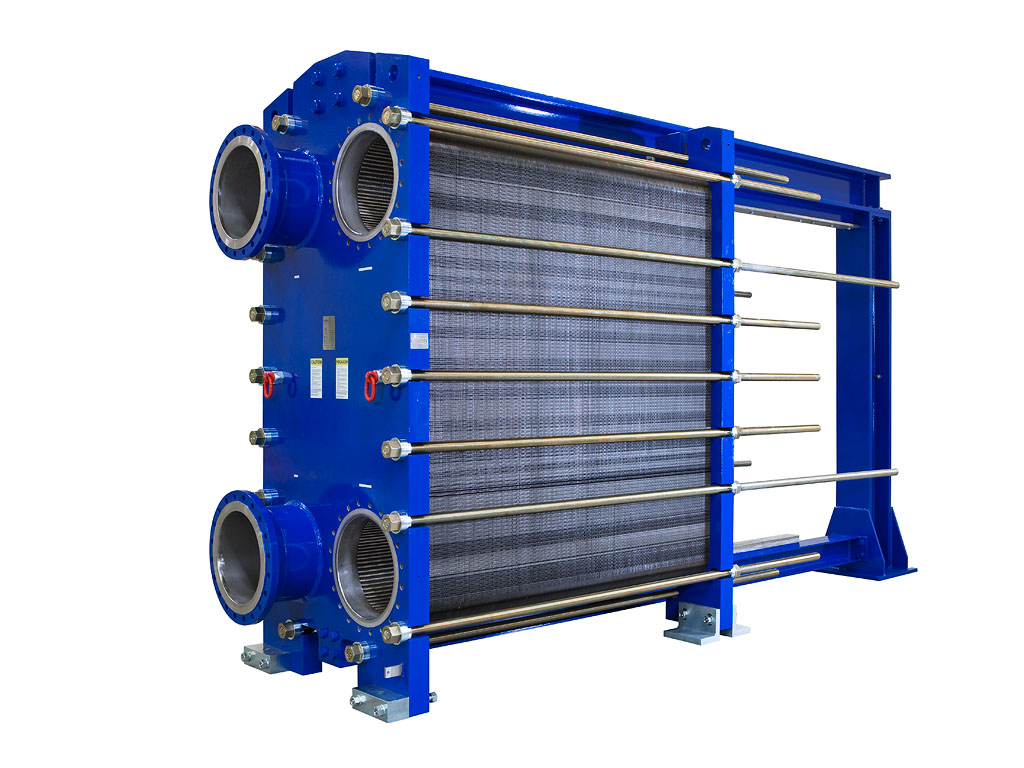

Plate Heat Exchangers

Plate – type marine heat exchangers are designed with set’s of multiple parallel plates that are bonded together in order to form the main cooler unit. The design of the plates is done in such a way that when they are placed next to each other they form passages for the fluids to flow. Gaskets are placed around the edges of each plate, in such a way that they prevent the fluids from mixing together. These gaskets are made of rubber material that has certain pressure and temperature constraints. As a result the gaskets are not suitable for high temperature and pressure applications.

Plate type Heat Exchangers are used for the cooling of lubricating oil, fresh water and acid or alkalic mediums. They are also used for heating fresh water, oil and drinking water.

Shell and Tube Heat Exchangers

Shell and Tube marine heat exchangers consist of a tube bundle that is placed inside the larger shell. These exchangers have orthogonal cells which cool the liquid that flows inside them. Most of the time they are bigger than their Plate counterparts and are builded in single or double configuration.

Quality Heat Exchangers for the Shipping Industry

Our company in collaboration with our partners, can fabricate most of the Heat Exchanger types used in the Shipping industry and Marine applications. More specifically we can provide your vessel with the following types:

- Air Coolers

- Steam Condensers

- Heaters

- Silencers

- Air Receivers

- Radiators

- Condensers

- Cascade Tanks

- Hydrophone Tanks

- Exhaust Gas Boilers

- Plate Type Heat Exchangers

- Fresh Water Generators

Furthermore, our products are certified by major classification societies (i. e CCS, DNV, BV, CRS, etc) upon the customer’s request.

Manufacturers & Types

Alfa Laval: JWP-16, JWP-26, DPU36C, M3-M30 series

Atlas Denmark: AFGU series

Sondex - Danfoss BV: DN25 - DN600 series

LHE: PE60L, HT151 NBR, HT232 ETC

Hisaka: GEA, DM15

APV: Mira, Elite models

| Maker | Korea | China | Japan | Europe |

|---|---|---|---|---|

| ALFA LAVAL | - | OEM | - | OEM |

| ATLAS DENMARK | - | - | - | GENUINE |

| LHE | GENUINE | - | - | - |

| SONDEX - DANFOSS | - | - | - | GENUINE |

Why Choose Us for Heat Exchanger Spares

Oceantech Shipping & Trading Ltd can provide your company with high-quality genuine spare parts for Atlas Denmark and Sondex - Danfoss heat exchangers from the Europe region. Moreover, we can cater OEM parts for Alfa Laval products from our supplier's network in China, Korea, Japan, and Europe. We also provide 18 month warranty for all our spares.

For more information please contact us and we'll prepare our spare parts quotation as soon as possible.

Tel: +30 2130337678

Email: oceantech@ost.gr